A BELFAST-based medical tech firm that specialises in 3D printing is one of 30 firms from the north helping develop thousands of new ventilators to tackle the Covid-19 crisis.

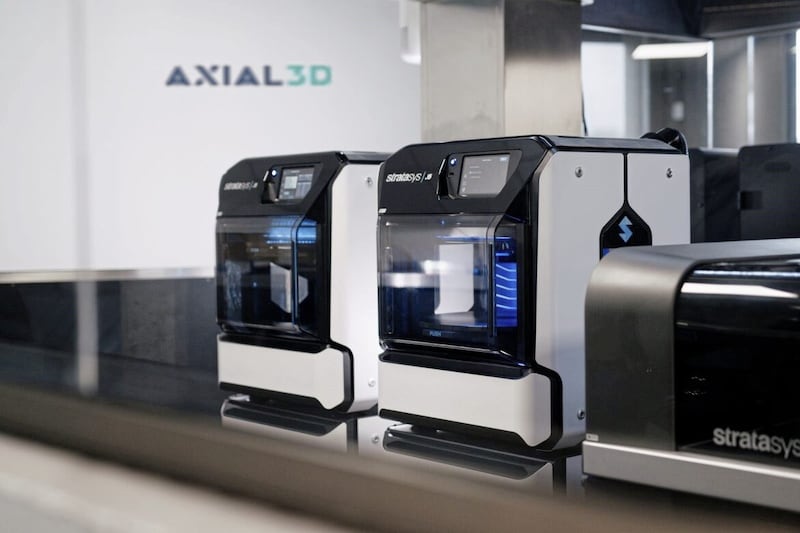

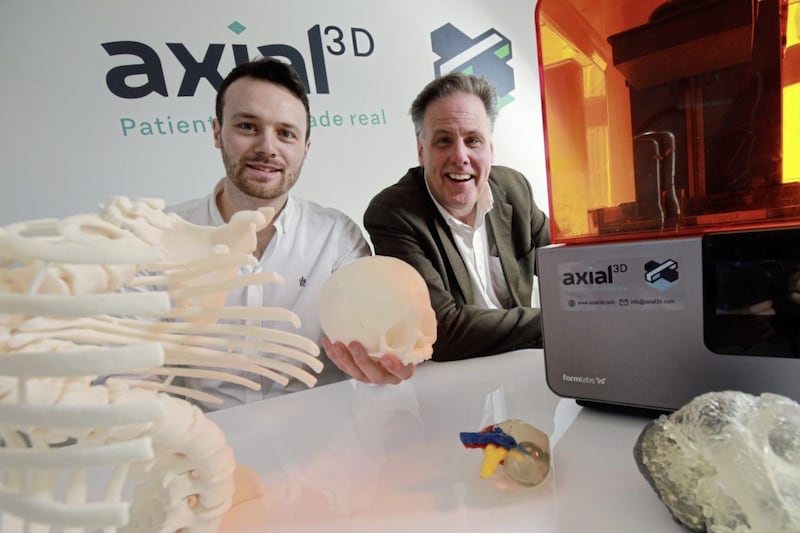

Axial3D creates models of the human anatomy to assist surgeons in critical operations. But the firm is now working on parts that will be used in new ventilators being built for the NHS.

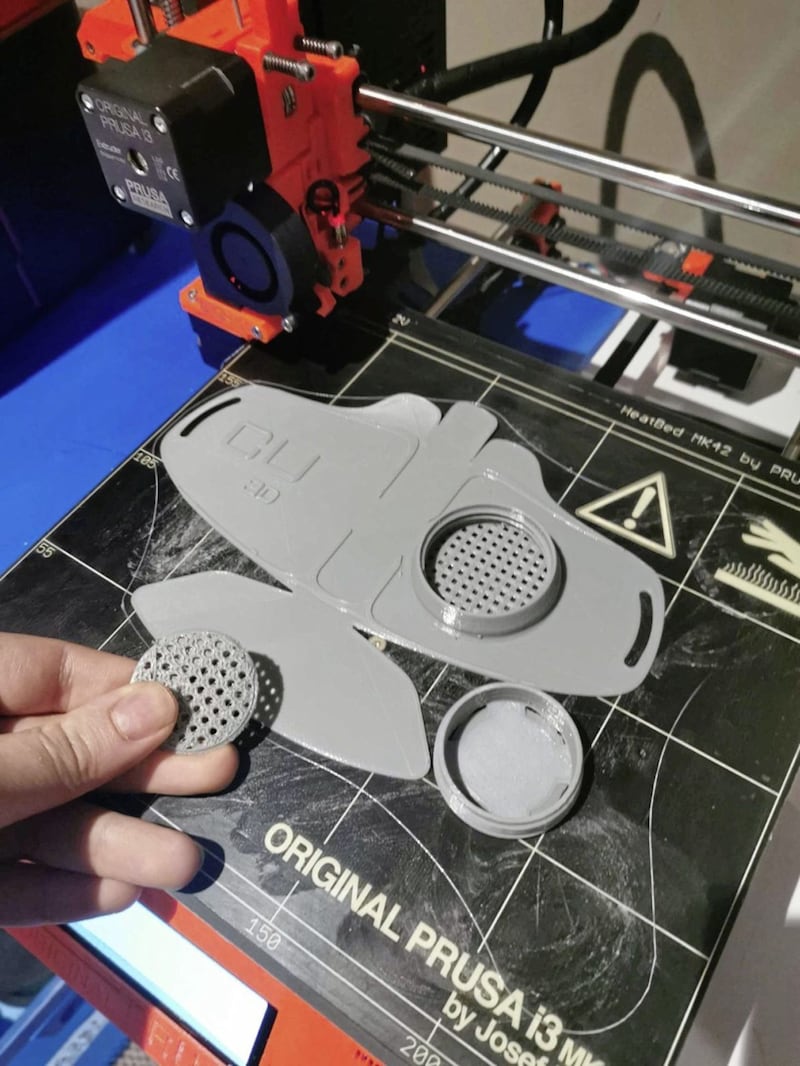

The company is also manufacturing valves and splitters for ventilators to enable the life-saving devices to support at least two patients in certain cases.

It’s one of 30 firms the Northern Ireland Executive said had come forward to help produce Rapid Manufactured Ventilator Systems (RMVS). They will join a UK-wide consortium with the aim of manufacturing 20,000 units for NHS England, which in turn will allocate to regions, including the north.

A further 40 companies are now involved in an initiative to produce personal protective equipment (PPE).

Most of Axial3D’s 30 staff are based at its Ormeau Avenue offices, but it also employs a number of people across the United States.

That connection has resulted in the Northern Ireland firm also joining a project that will print hundreds of thousands of face shields for healthcare workers in North America.

Axial3D’s chief executive, Roger Johnston said the company has spent the past 4.5 years developing patient specific 3D models of anatomy for some of the most complex surgeries.

“If you have a trauma from a car accident, we take the CT scan and turn that into a micro-millimetre exact representation of your leg. That allows the surgeon to see exactly the trauma as opposed to trying to guess it from a CT scan.”

But with many surgeries being placed on the back burner during the coronavirus crisis, Axial3D has offered to help health trusts struggling to find certain parts.

“We’re not doing any of this to make profit, this is just out little part we can do to help,” said Mr Johnston.

“We want to know if there are trusts out there that need help, that we can print things for. If there are people out there struggling for parts, we will turn the resources of our modest company to helping them.”

Describing the valves and splitters already being printed by the firm for use in ventilators, the chief executive said: “The splitter allows two or more patients to use the same ventilator. So instead of having to buy expensive ventilators, especially when patients are recovering.

“Once they are past their peak they don’t need as much oxygen, so you can put multiple patients on the same ventilators.”

Despite seeing “a blip” in business due to hospitals gearing up to battle Covid-19, Mr Johnston said the firm is confident demand for its models will return as healthcare returns to normality.

“For good or bad, our business is a critical business that will potentially become more urgent as hospitals come back and that’s really our key job, to make sure we can help hospitals recover surgical capacity as quickly as possible and as efficiently as possible.

“For now, we are using lots of our resources to help treat Covid-19.”

Praising the response of local companies, Health Minister Robin Swann said it has been heartening indeed to see industry stepping up to the task.

“Nearly 100 local companies have come forward offering their skills and expertise to assist the effort to provide those on the front line with the precious resources that they need.”